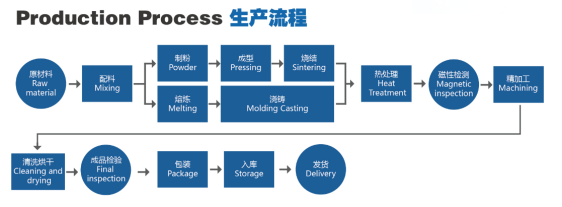

We have a strong production scale of sintered AlNiCo permanent magnets that can produce performance

Alnico 2-8 rating. The annual output is nearly 1000 tons. We have sintered and cast Alnico. all

The material for sintered AlNiCo is exactly the same as for cast AlNiCo.

Powder metallurgy.

Proprietary technology and advantages

● High-performance products with mature technology and stable performance;

● Fully automatic detection of magnetic flux equipment for all products;

● It can stably produce thin-walled deep-hole, special-shaped, precision micro products, and the processing technology is stable

● Can produce all-round maximum magnetic energy AlNiCo96 products

Sintered AlNiCo Applications

Sintered AlNiCo is suitable for the production of complex switches, light, thin and small products, and is widely used in instrumentation and

Instruments, communications, magnetic switches and various sensors.

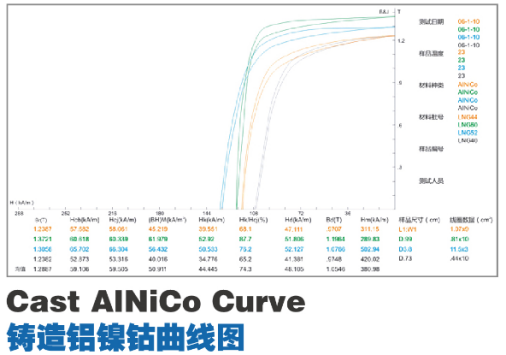

Foundry AlNiCo Applications

Cast AlNiCo magnets are mainly used in auto parts, instrumentation, electroacoustic, electrical

It has low temperature coefficient and high temperature resistance

It has the characteristics of resistance, moisture resistance, not easy to be oxidized, and good working stability.