Introduced in the early 1980s. Its main component is Nd2Fe14B, which has high magnetic properties.

Its maximum energy density (BHmax) is more than 10 times that of ferrite magnets; the maximum

Operating temperature up to 250 degrees Celsius. In addition, it has good mechanical properties, which can

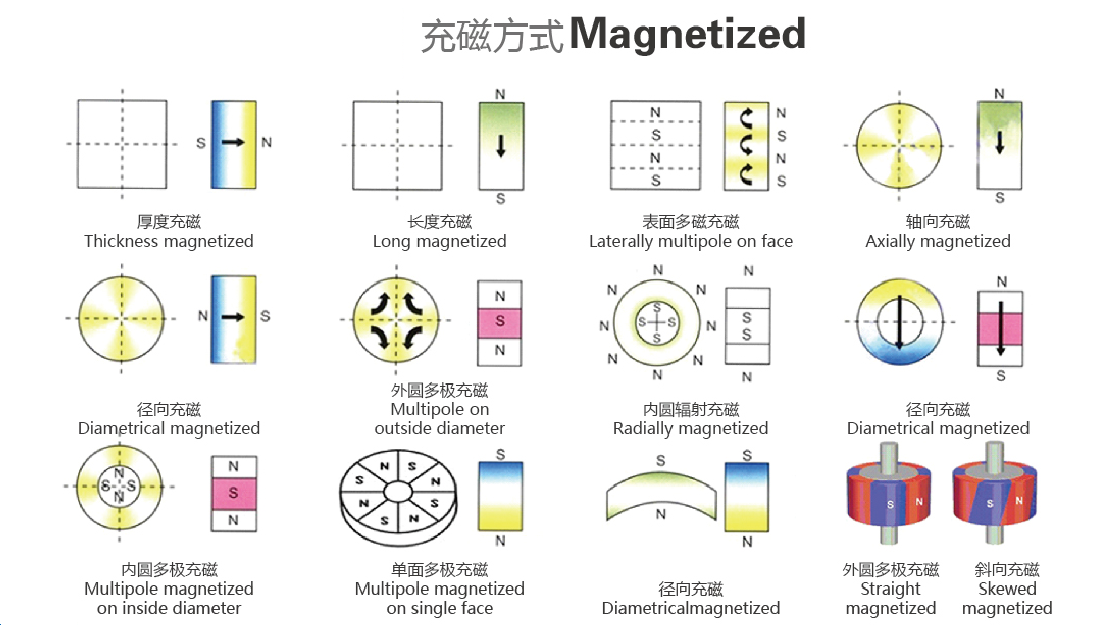

Suitable for different processing methods such as grinding, wire cutting and drilling; because

Corrosion resistance is weak, the surface must use different coatings to match different

Requirements (such as zinc, nickel, gold, epoxy, etc.)

Proprietary technology and advantages

1) High performance

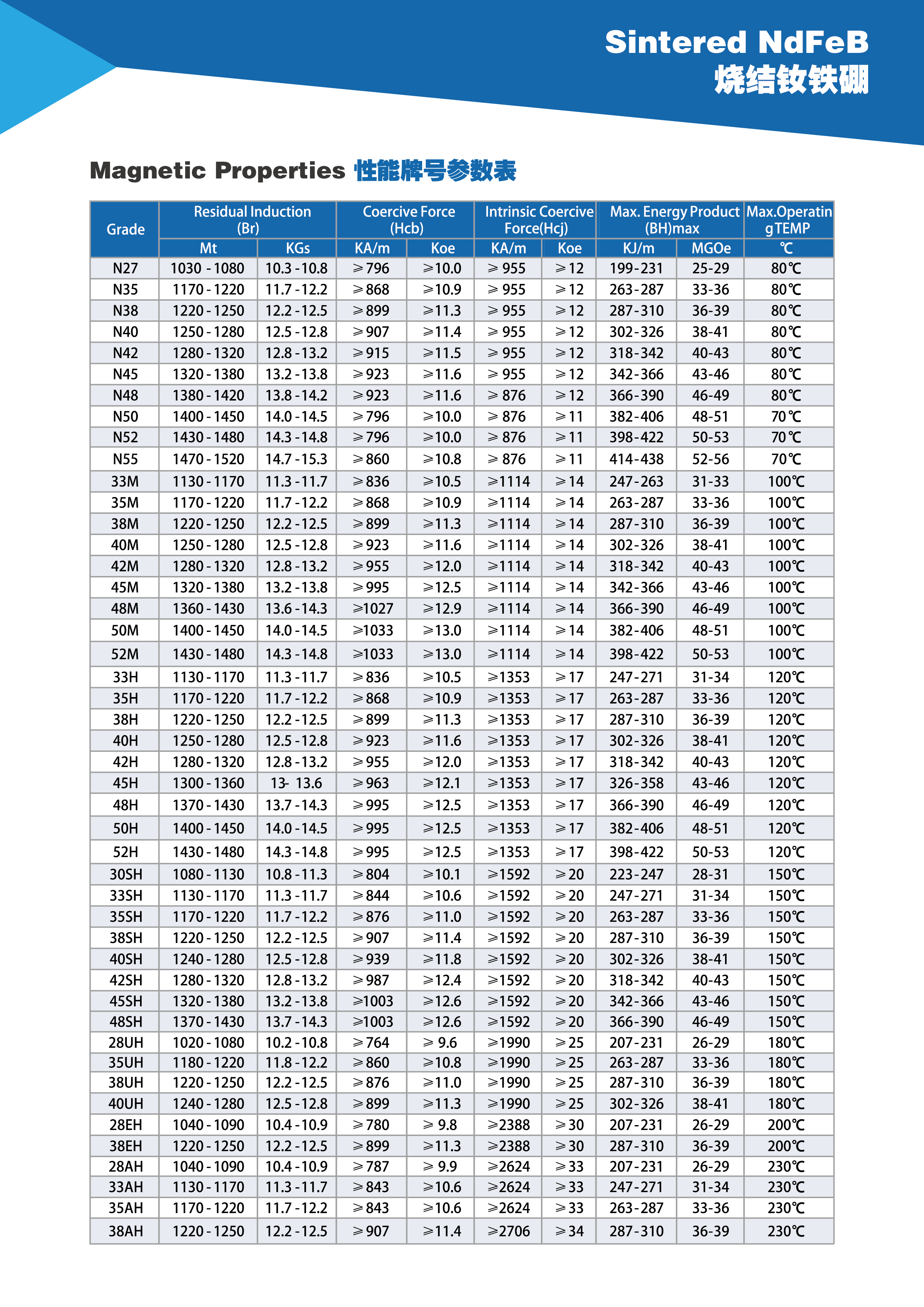

High-performance Senlong magnets can reach: N55, 55M, 50H, 48SH, 45UH, 42EH, 38AH, etc.

2) High consistency

The Cpk of remanence (Br) and intrinsic coercive force (Hcj) is much higher than 1.67. consistency

Surface magnetic field and magnetic flux can be controlled within +/- 1%.

3) High working temperature

Our magnets can meet operating temperature requirements and have excellent temperature resistance.

The AH series has an ultra-high coercivity of 40 kOe and can replace samarium cobalt magnets in most applications.

3) High working temperature

Our magnets can meet operating temperature requirements and have excellent temperature resistance.

The AH series has an ultra-high coercivity of 40 kOe and can replace samarium cobalt magnets in most applications.

5) Low weight loss

Senlong ultra-high magnets have a long life and the specifications are as follows: PCT: 130°C,

Humidity 100%, vapor pressure 2.7bar, 20 days, average low weight loss <2mg/cm2

Application field

Information industry, defense industry, automobile industry, wind power generation, home appliances, instrumentation

and instruments, medical equipment, as well as magnetics, instruments, etc...