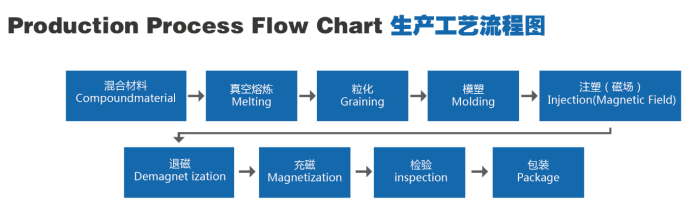

The plastic magnetic rotor and magnetic ring are magnets formed by injection molding,

After mixing with magnetic powder and resin. Neat and flawless appearance; high precision,

Good stability, no need for reprocessing, stable performance and impact resistance. shape

Can be complex and microscopic. They are the necessary signal source and constant magnet source.

It is superior to other magnetic things. Mainly used in industrial automation equipment, DC motors,

Shaft energized fan motor, transmission air conditioner motor, instrument motor, etc.

Proprietary technology and advantages

●Injection arc magnet: suitable for all kinds of micro motors, with radial orientation and high magnetic properties.

The magnetic flux efficiency is high, it is not easy to break, and it does not drop chips. The micro-motors that require starting voltage can be started at low voltage.

●Injection magnetic ring: used for various automatic adjustment motors, instrumentation, intelligent industry and precision sensors

field. The minimum magnetic pole distance of ABS induction hydraulic pressure can reach 1.5mm.

●Plastic magnetic rotor: mainly used for brushless DC motors, such as air conditioners, home appliances and synchronous motor rotors

and magnetic couplings, etc. Can be integrally injection-molded with the shaft.

● Developed the highest injected NdFeB magnetic BH (msx) up to 15.3M, with excellent precision and magnetic energy.

Application field

Mainly used in industrial automation equipment, D/C motor, axial flow fan motor, transmission air conditioner

Motors, instrumentation motors, etc.